Pioneering the future of Orthopaedics.

Associate Professor Saulo Martelli stands at the forefront of research that is reshaping how we understand and treat joint conditions. As Program 2 Lead at the Australian Research Council Industrial Training Centre for Joint Biomechanics, he has been guiding a bold initiative that fuses robotics, ultrasound, and biomechanics into a single, powerful vision. It is a vision that is as ambitious as it is practical: to transform cutting‑edge engineering into better surgical procedures, safer implants, and more effective rehabilitation for patients.

Bringing Robots and Ultrasound into the Lab.

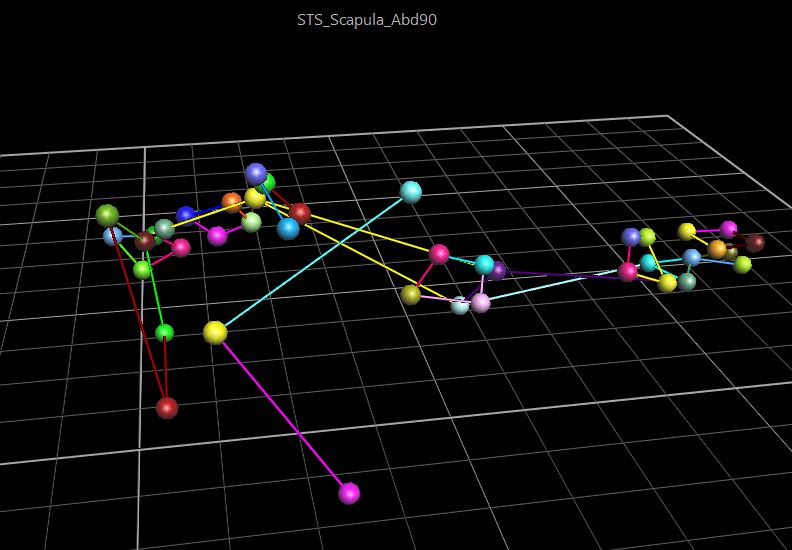

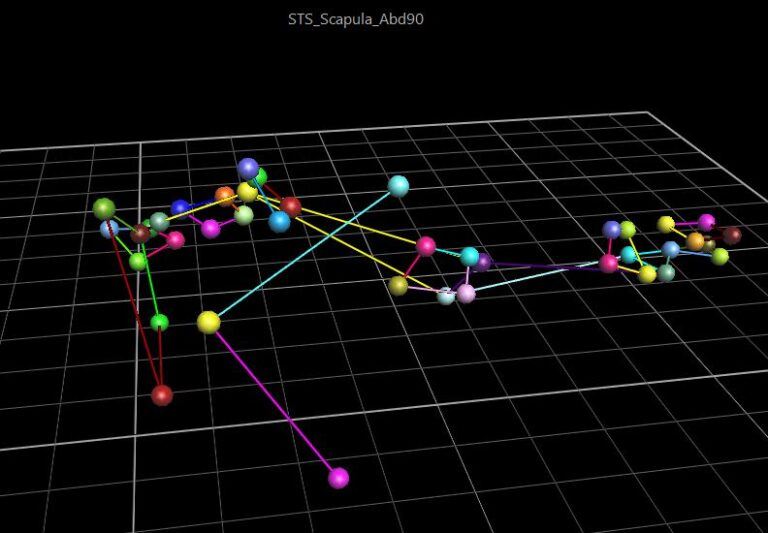

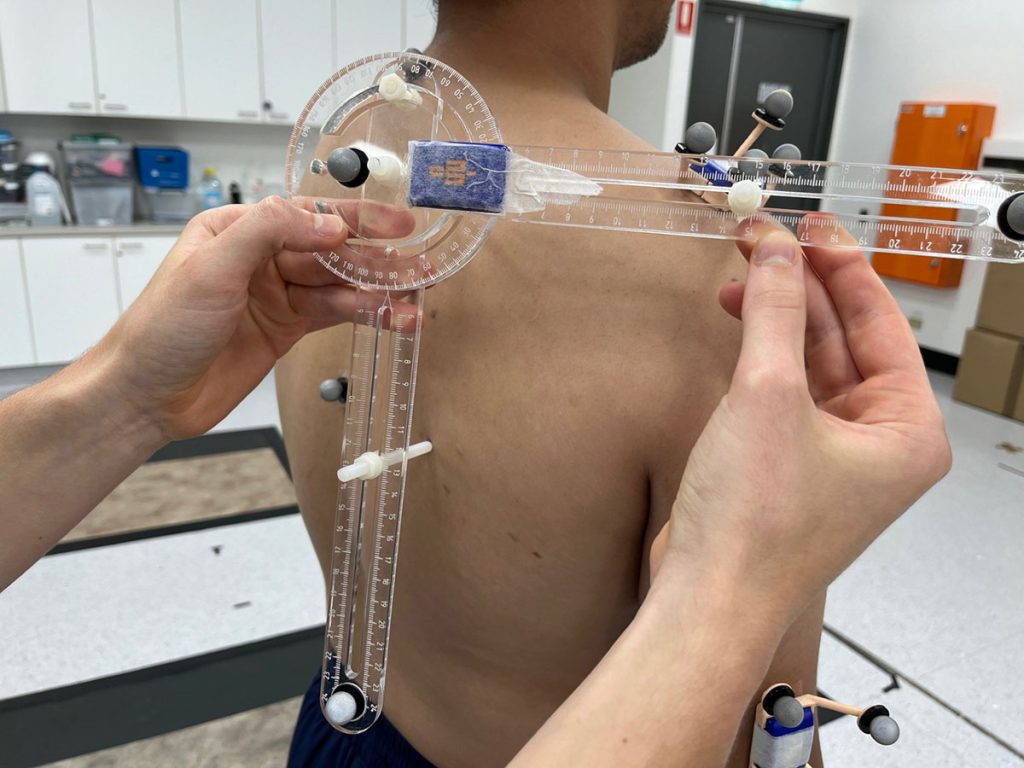

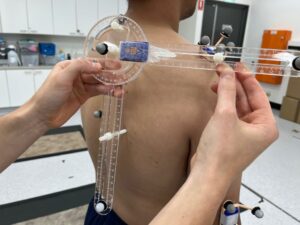

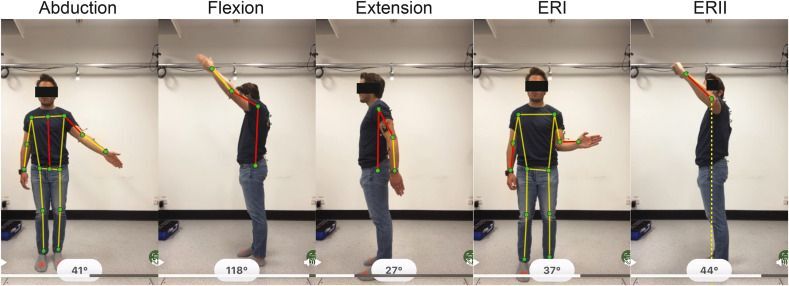

Program 2 is devoted to Robot Assisted Testing and Surgery, a field that demands both technical mastery and clinical insight. Joints like the shoulder endure complex, three‑dimensional forces that shift with every movement, making them a challenge to study and replicate. Martelli’s approach harnesses robotic systems capable of mimicking these changing loads, paired with high‑frequency ultrasound ADVANCED imaging that can detect microscopic changes in bone and implant structures. This unique combination allows his team to capture the intricate interplay between movement and stability in ways that were previously out of reach.

Transforming Shoulder Surgery with Data‑Driven Precision.

The insights gathered in the lab are more than academic data points, they are stepping stones toward tangible surgical improvements. By understanding precisely how an implant behaves under real‑world conditions, Martelli’s work helps guide surgeons toward more accurate shoulder replacements. These advances promise to increase the precision of surgical interventions, reduce recovery times, and improve long‑term joint function. In parallel, the lab’s rigorous testing protocols ensure that implants are evaluated under the most realistic and demanding conditions before ever reaching a patient.

Cracking the Code of Virtual Trials.

One of Martelli’s most notable breakthroughs emerged from a Zimmer Biomet collaboration with colleagues Christine Mueri, Lukas Connolly, Jeff E. Bischoff, and Philippe Favre. The team tackled a key limitation in in silico clinical trials: computer simulations of patient outcomes. Traditional high‑fidelity models can take over an hour to run for a single case, are extremely complex in their technicality and require considerable expertise to operate. Previously impossible in surgical planning, the ability to inform surgeons if an implant will be stable months after surgery is becoming possible through developing a surrogate model: a fast, predictive algorithm trained on previous simulation results that delivers results in milliseconds while retaining exceptional accuracy. This leap in speed allows vastly more virtual patients to be modelled in less time, enriching datasets for implant evaluation, personalised surgical planning, and rehabilitation strategies.

The Power of Collaboration

Central to Program 2’s success is its close partnership with industry, particularly Zimmer Biomet. Through the ARC Training Centre’s Impact Pathway, academic innovation collaborates with real‑world production expertise to improve diagnostic response and patient outcomes.

Taking the Vision to the World Stage

Over the coming year, Martelli’s work will be presented at major international conferences, including the ISTA 36th Annual Congress in Rome, the MDIC Symposium on Computational Modeling & Simulation in Maryland, the MDIC Annual Patient Summit, and the 9th Asian Pacific Congress on Computational Mechanics in Brisbane. These events will showcase the potential of combining robotics, ultrasound, and computational modelling to revolutionise how joint surgery is planned, executed, and assessed.

A Data‑Driven Future for Joint Care

The story of A/Prof Saulo Martelli’s Program 2 research is one of integration, bringing together engineering precision, clinical needs, and technological innovation to redefine standards in orthopaedics. By closing the gap between laboratory research and patient care, Martelli and his collaborators are charting a course toward surgeries guided by rich, real‑time data and supported by rigorous pre‑clinical validation. It is a vision in which each patient’s journey to restored mobility is shaped by science, driven by technology, and delivered with precision.